CellFlon® CL ePTFE gasket tape

Special gasket tape for Chlor-Alkali Electrolysis-Cells

KWO® CellFloi is the optimised gasket tape for a safe and cost-effective use in Chlor-Alkali Electrolysis-Cells.

The micro-cellular structure of the used ePTFE material ensures better adaptability, lower cold-flow and higher gasket stress.

Key Features

Benefits

Product data

Material

100 % pure virginal PTFE with microcellular structure

Chemical Resistance

Universally resistant except to dissolved and molten alkaline metals and elemental fluorine at raised temperatures and pressures

Resistance to Ageing

in the permissible range of application there is no ageing of KWO ® Cellflon ® CL

Depending on storage conditions the adhesive force of the glue strip can change.

Temperature Range of the Material

-240°C to +270°C intermittent to +315 °C

Recommended Conditions

-240 °C to +150 °C at simultaneous operating pressure up to 16 bar, depending on installation and service conditions

Pressure Range

pressure resistance generally depends on the installation and service parameters, please pay attention to proper installation

Vw0® CellFlon® CL

ePTFE gasket tape

Universal Use

KWO® CellFlon® CL Gasket Tape for Chlorine-Eloctrolysis-Cells with fluor-polymer-frames is fast and easy to install. It can

be used without the need of pre-cutting. The improved malleability of KWO® CellFlon® CL is also making the installation at the edges of the cell easier.

Typical Properties :

DIN EN 13555

Qmin (0,01) = 25 MPa

QS min (0,01) =5 MPa

QS max = 150 MPa

ASTM F-36

Compressibility = 68%

Recovery = 10%

ASTM F-38

Creep Relaxation = 65%

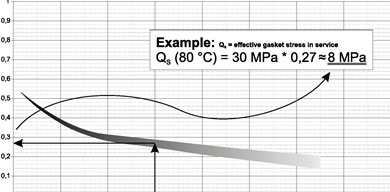

Relaxation Factors CellFlon white with QA = 30 MPa

Quick maintenance

KW® CellFlon® CI gasket tape is optimised for manufacturing on site gasketings for Chlor-Alkali Electrolysis-Cells. The improved installation and removing features are saving time and costs.

General Information

All technical information and advice are based on our experience and are to the best of our knowledge, but do not state any liability by our company. Specifications and values must always be checked by the customers, for they are the only ones that can judge the efficiency of a product taking into account all of the on-site operating conditions.

Easy Installation

Minimize installation and maintenance time!

The self adhesive backing makes KWO® CellFlon CL Gasket Tapes easy and quick to install.

Completely clean the sealing surfaces and remove any dirt, corrosion, oil, or leftover gasket material.

Cut the first end of the gasket tape using the sloping cut shown in Fig. 1. Remove the protective paper and start next to a bolthole, sticking the tape at the centre of the sealing surface.

Stick the gasket tape around the flange circumference and close the gasket using a second sloping cut for the ending (see Fig. 2). Leave in any case more than 100% material thickness at the overlap – the endings will interlock and a safe jointing will be produced.

Technical Support

For detailed selection criteria, technical support for installation and maintenance as well as information on other sizes please call.