UNISEAL

Aramid fiber sheets and gaskets.

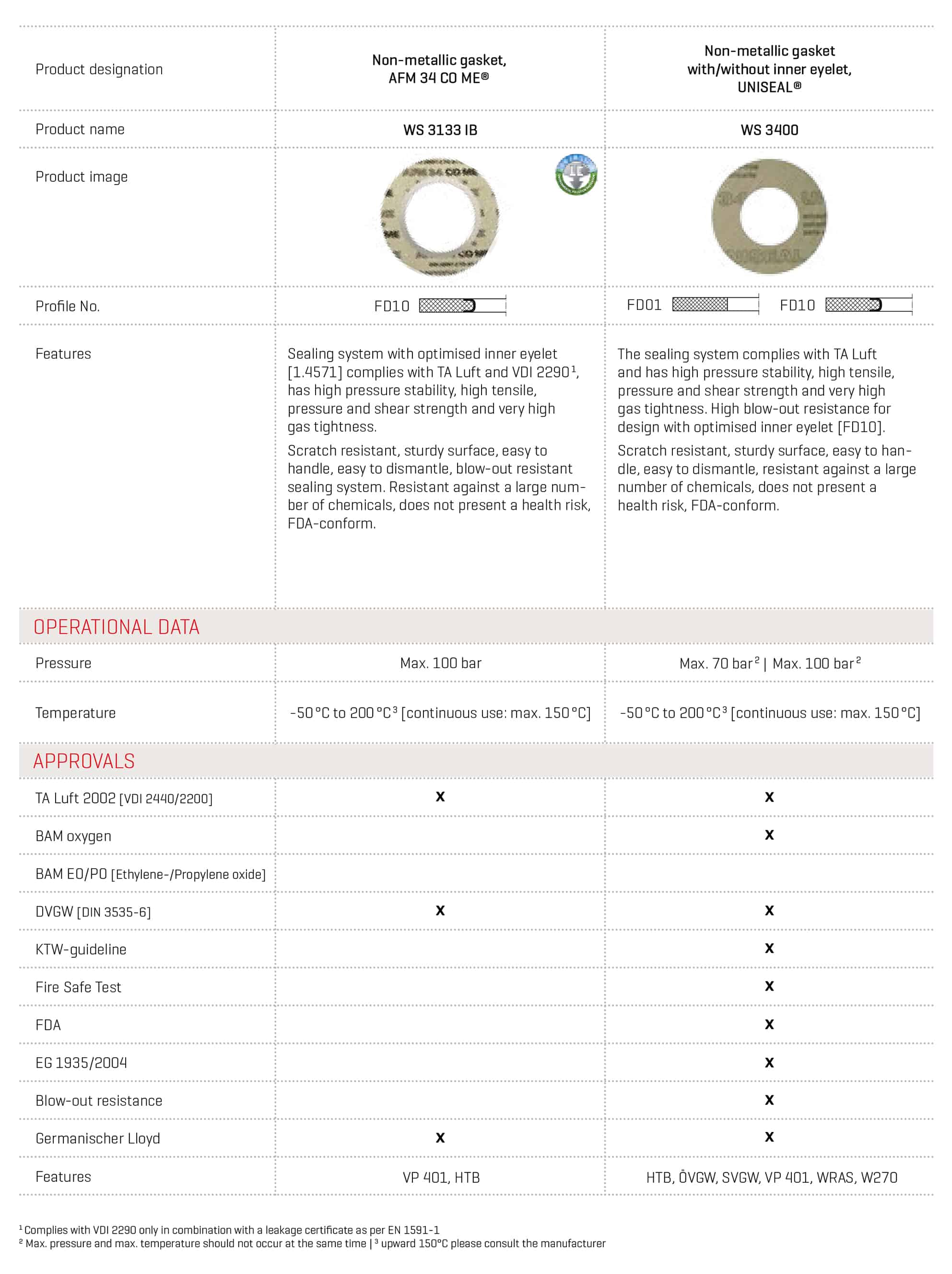

Item No: WS 3400

Description

IDT-UNISEAL 3400 is a universal non-metallic gasket – sheet material which is high-strength and very homogeneously compound made from high quality aramid fibers, inorganic fillers and optimised elastomers; it does not contain any physiologically harmful substances. UNISEAL® has a separating top [TD 2] with a high coefficient of friction on both surfaces as standard. This makes removal easier.

Properties

Applications

Product Range

Technical delivery conditions as per DIN 28091

- Dimensions: 1500 x 1500 mm [standard format], 1500 x 3000 mm, 1500 x LI500 mm

- Available thicknesses: 0.3; 0.5; 0.75 ;1.0; 1.5; 2.0; 3.0, LI. and 5.0 mm

- Dimensions: as per DIN EN 151LI-1, ASME/ANSI, DIN 7603

- Non-standard

- Made from segments

- Frames

Additionally: IDT Profile Overview I FD Series

Additional designs

- Envelope gaskets made from TFMTM with non-metallic insert