Unifluor Sheets & Gaskets ǀ PTFE with fillers

Biaxial-oriented ptfe ws 7550 | ws 7551 | ws 7553

Description

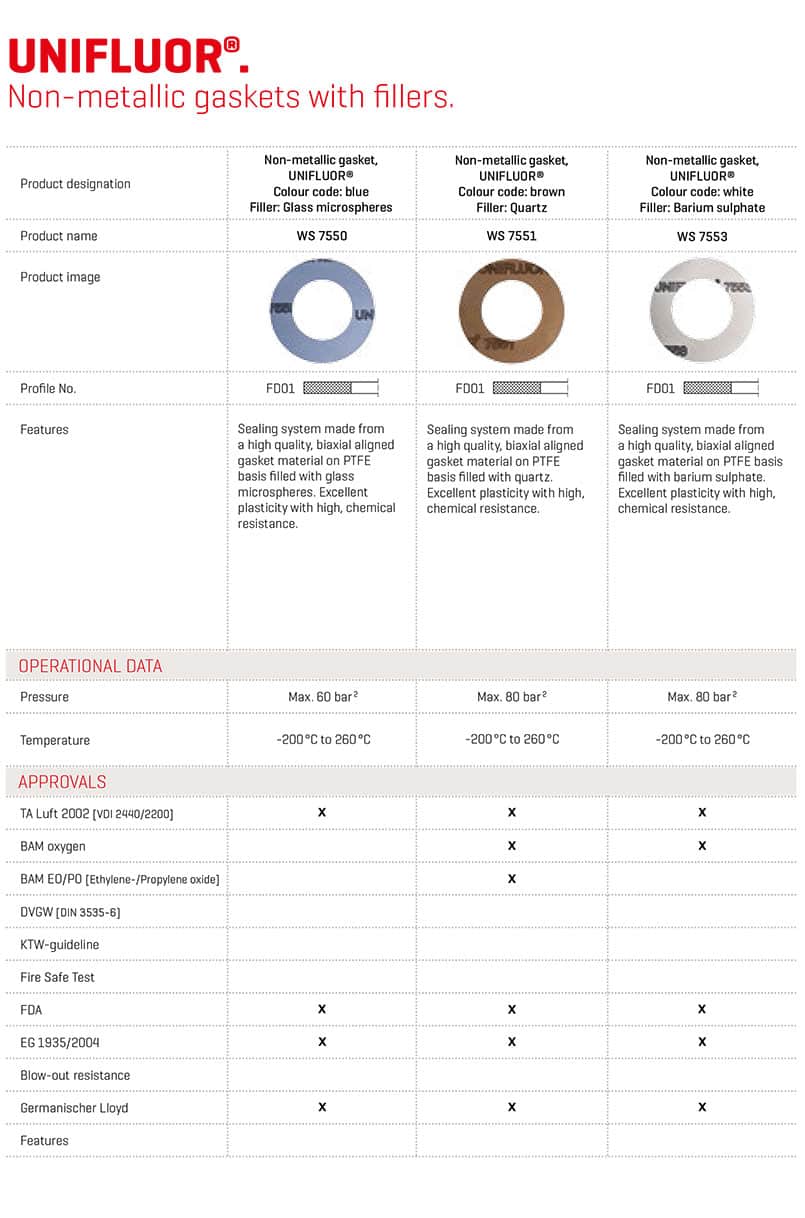

UNIFLUOR® gasket sheets are manufactured in a special production process which causes a very strong, biaxial orientation of the PTFE molecules. This results in a significant reduction of the negative creep and setting behaviour which is typical for classic PTFE. The sheets are also homogeneously filled with specific sub¬stances in addition to the optimisation of sealing technological properties and depending on the application area. Primarily, three types of fillers are used in gasket sheets as standard. They can be distinguished from the outside by the different colouring.

Standard fillers are:

Properties

Applications

Product Range

Technical delivery conditions as per DIN 28091

- Dimensions: 1500 x 1500 mm [standard format]

- Available thicknesses: 0.75 ;1.0; 1.5; 2.0; 3.0 mm

- Dimensions: as per DIN EN 1514-1 and DIN EN 12560-1 or ASME B 16.21 as well as non-standard sizes, made from:

- UNIFLUOR® WS 7550 [blue]

- UNIFLUOR® WS 7551 [brown]

- UNIFLUOR® WS 7553 [white]

Additionally: IDT Profile Overview I FD Series

Seals made from above mentioned PTFE materials are also available with inner eyelets and/or outer eyelets.

Additional Designs

- TFMTM-envelope gasket with non-metallic insert made from UNIFLUOR® WS 7550 and/or corrugated metal ring for food and pharmaceutical applications

- UNIFLUOR® ePTFE CellFlon® tape WS 7501 [blue] and WS 7534 [white]