Ring Joint Gaskets

Description

Ring Joint Gaskets are fully metallic, milled gasket constructions, which are mainly used for applications with high pressures and/or temperatures. Typical applications are in refineries in the petrochemical industry. With regards to surface quality, that the flange and the gaskets have to have an accurately treated surface without scratches and damage.

IDT-RTJ-gaskets are manufactured following ASME B16.20 [DIN EN 12560-5] and API 6A for flanges according to API 6B and ASME/ ANSI B16.5 and ASME/ANSI B 16.47. Every ring joint gasket is allocated an identification number [R, BX, RX] which is described in the standard with regards to its dimensions using the ring number. A roughness of 1.6 Ra [6.4 Rz] should not be exceeded for the contact surfaces of the types R and RX; type BX requires a roughness of max. 0.8 Ra [3.2 Rz].

Gasket & Profile Styles

Ring-Joint-Gaskets are commonly distinguished according to two design:

RTJ Gaskets With Osculating Radius

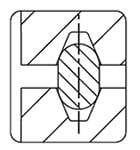

Oval

Style R | Profile RJ01

The oval form can also be used in flange connections with RTJ¬groove [flank angles 23°] according to the above mentioned norm. The spherical surface of the gasket is pressed against the cone surface of the flange when clamping it, which creates a linear contact between flange and gasket. The metal ring is deformed further with increasing assembly force and the contact surface is widened. The size of the sealing surface there¬fore depends on the applied assembly force; the oval shape is preferred if the bolt forces are low and the radial elongations/ offsets vary.

Ring Joint Gaskets With Raised Sealing Surface

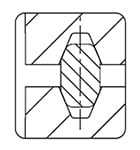

Octagonal

Style R | Profile RJ10

The octagonal design can also be used in flange connections with RTJ-groove [flank angles 23°] according to the above mentioned norm. Different to the oval form, an extensive stress is created right from the start on the contact surface gasket/flange. The sealing surface size is therefore independent from the assembly force; the octagonal type is the the preferred design.

RTJ-Gaskets With Raised Sealing Surface

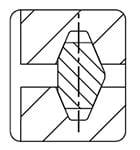

Octagonal

Style RX | Profile RJ20

The type RX is an optimised design of style R: octagonal. The gasket type fits the same groove flange as described for the R style and can also be easily used or replaced in this application. The RX style was optimised in such a way that the overall seal¬ing force is increased via the internal pressure, and which in turn influences the gasket properties positively. This design can be fitted with an additional pressure balancing hole.

RTJ-Gaskets With Raised Sealing Surface

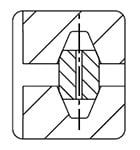

Octagonal

Style BX | Profile RJ30

The BX style is also a pressure optimised design; BX style can, however, not be exchanged with other styles and has been deve¬loped specifically for the API 6BX flange. This design can be fitted with an additional pressure balancing hole.

Properties

Applications

Product Range

Dimensions following norm specification of ASME B16.20 [DIN EN 12560-5] and API 6A, flanges according to API 6B and ASME/ANSI B16.5 and ASME/ANSI B 16.47

- Style R

Dimensions following ASME B 16.20, API Std 6 A for flanges as per ASME B16.5 and ASME B16.47 series A as per DIN EN 12560-5 - Style RX

Dimensions following ASME B 16.20 or API Std 6 A for API 6B-flanges - Style BX

Dimensions following API Std 6 A for API 6BX-flanges

Additionally: IDT Profile Overview | RJ Series

Materials

Because Ring Joint gaskets are used in extreme operating condi-tions, it is of utmost importance to select the most suitable, metallic material. In addition to pressure and temperature, the resistance towards the conveyed media has to be con¬sidered. The hardness of the gaskets should usually be lower than that of the flange material in order to prevent mechani¬cal damage to the flange.

The maximum values for the hardness are specified for the different materials as per ASME B 16.20 / API 6A.

| Material | DIN/EN | AISI/ASTM | Identification | Max. Hardness HB [Brinell] |

|---|---|---|---|---|

| X5CrNiMo17-12-2 | 1.4401 | 316 | S316 | 160 |

| X6CrNiNb18-10 | 1.4550 | 347 | S347 | 160 |

| X6CrNiMoTH 7-12-2 | 1.4571 | 316TÌ | S316TI | 160 |

| X2CrNiMo17-12-2 | 1.4404 | 316L | S316 | 160 |

| 12CrMo195 | 1.7362 | A182 | F5 | 130 |

| Soft iron | 1.1003 | Soft iron | D | 90 |

Additional materials on request

Marking

The marking is done on the outer surface of each gasket.