PTFE Gasket & Sheets | 3MTM DyneonTM TFMTM

WS 7110 | WS 7115 | WS 7221

Description

PTFE Gasket-IDT sheets are made from high quality 3MTM DyneonTM TFMTM. The basic characteristics of PTFE [polytetra¬fluoroethylene] are based on the special molecular structure of the fluorine and carbon atoms; both chains have an extremely strong bond. The carbon network is hermetically sealed by the fluorine atoms which makes a chemical attack extremely hard and the PTFE therefore becomes resistant to chemicals and solid.

The pharmaceutical-chemical industry requires low per¬meation for sealing applications, high chemical resistance, solid mechanical resilience and easier processability. Only few materials, mostly on fluoropolymer basis, combine these advantages. TFMTM, a PTFE of the second generation, has proven itself. TFMTM distinguishes itself from classic PTFE by the additionally applied modifier. The particles melt more easily into a dense, low pore poly mer structure due to the achieved, more homogeneous crystalline structure; as a result the tightness is significantly improved. A further disadvantage of classic first generation PTFE is that it flows under load [cold flow] and resulting in a loss of surface pressure in clamped condition. This negative characteristic has been significantly improved with the development and gasket technology application of TFMTM and the cold flow behaviour has been optimised. An additional modification can be achieved in a finishing process by mixing in filler or aggregates. During recent years, the use of the modified compound TFMTM 4105 with 25% glass fiber content has stood the test in the gasket technology practice. Semi-finished products and sheets as the source material for non-metallic PTFE gaskets are produced in a press-sinter process.

Properties

Applications

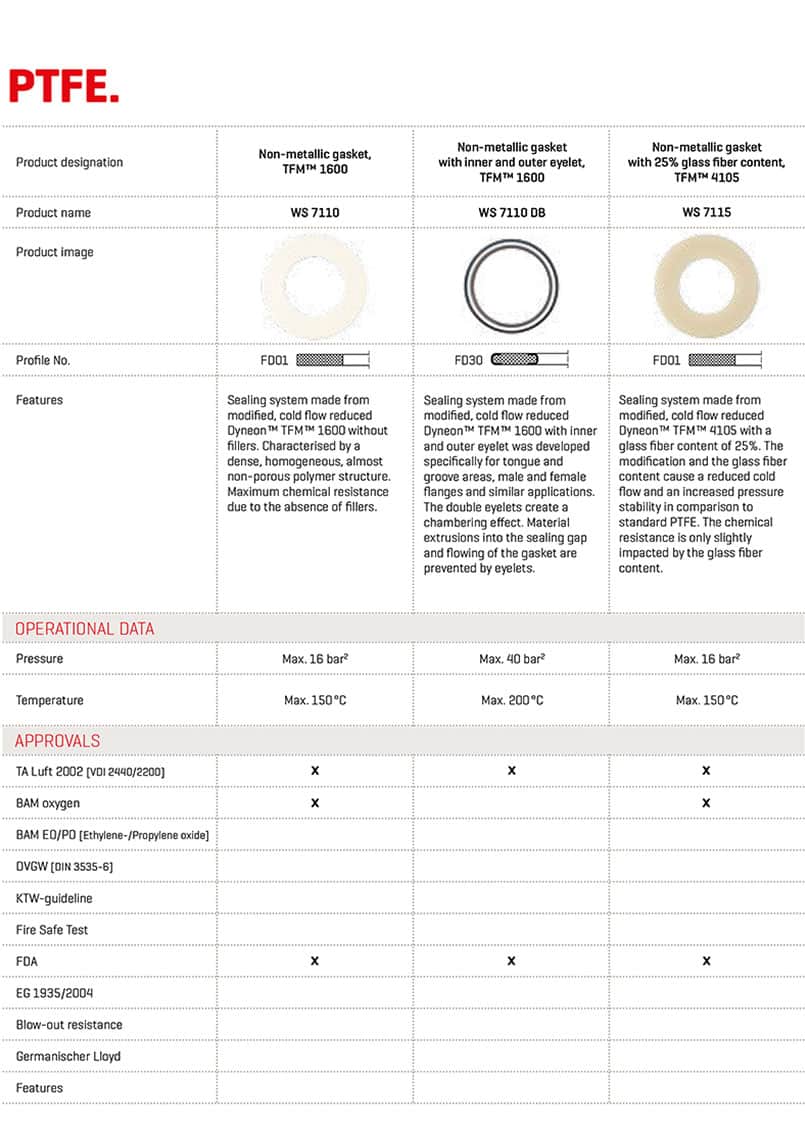

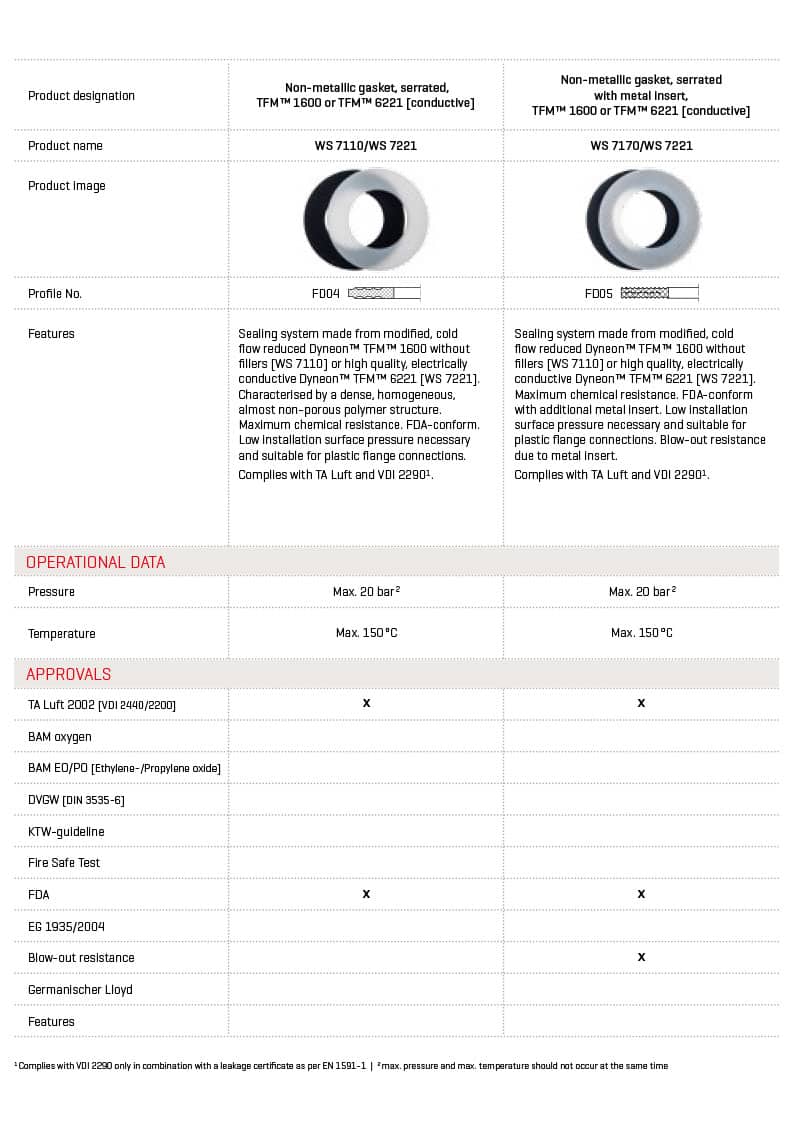

Product Range

Gaskets made from above mentioned materials are also available with inner eyelets and/or outer eyelets.

Additionally: IDT Profile Overview | FD Series

Additional Designs