SIGRAFLEX® Graphite Sheets & Gaskets

SIGRAFLEX® UNIVERSAL PRO & SELECT, HOCHDRUCK, HOCHDRUCK PRO, MF

WS 3862 I WS 3865 I WS 3885 I WS 3888 I WS 3875 DB I WS 3830IB I WS 3870 DB

IDT-graphite sheets and seals consist of high quality SIGRAFLEX® material. For the production of SIGRAFLEX® products, flaked natural graphite is used which has a good crystalline structure. The high purity of SIGRAFLEX® graphite gasket is determined by the raw materials and ensured by the quality of mechanical, chemical and thermal cleaning processes.

We are a most trusted name among the topmost graphite gasket manufacturers and suppliers in India. Our Graphite sheets are manufactured without reinforcement, metal-reinforced and/or waterproofing whilst the metal reinforcement can be done with sheet reinforcement or smooth stainless steel foils. The graphite sheets have higher strength, gas tightness, scratch resistance and non-adhering surfaces thanks to the special waterproofing.

Sigraflex Graphite Sheets and Gasket Properties

Applications

Sigraflex Graphite Sheets And Gasket Product range

Technical delivery conditions as per DIN 28091

- Available thicknesses: 1.0; 1.5; 2.0; 3.0, LI.0 mm

- Available dimensions: 1000 x 1000 mm and 1500 x 1500 mm [standard format]

- SIGRAFLEX® – foil/gasket sheet

- SIGRAFLEX® – tape

- SIGRAFLEX® – foil pressed into packing rings

- Dimensions: as per DIN EN 151L-I-1 and DIN EN 12560-1 or ASME B 16.21 as well as non-standard sizes, made from:

- SIGRAFLEX® UNIVERSAL [WS 3862]

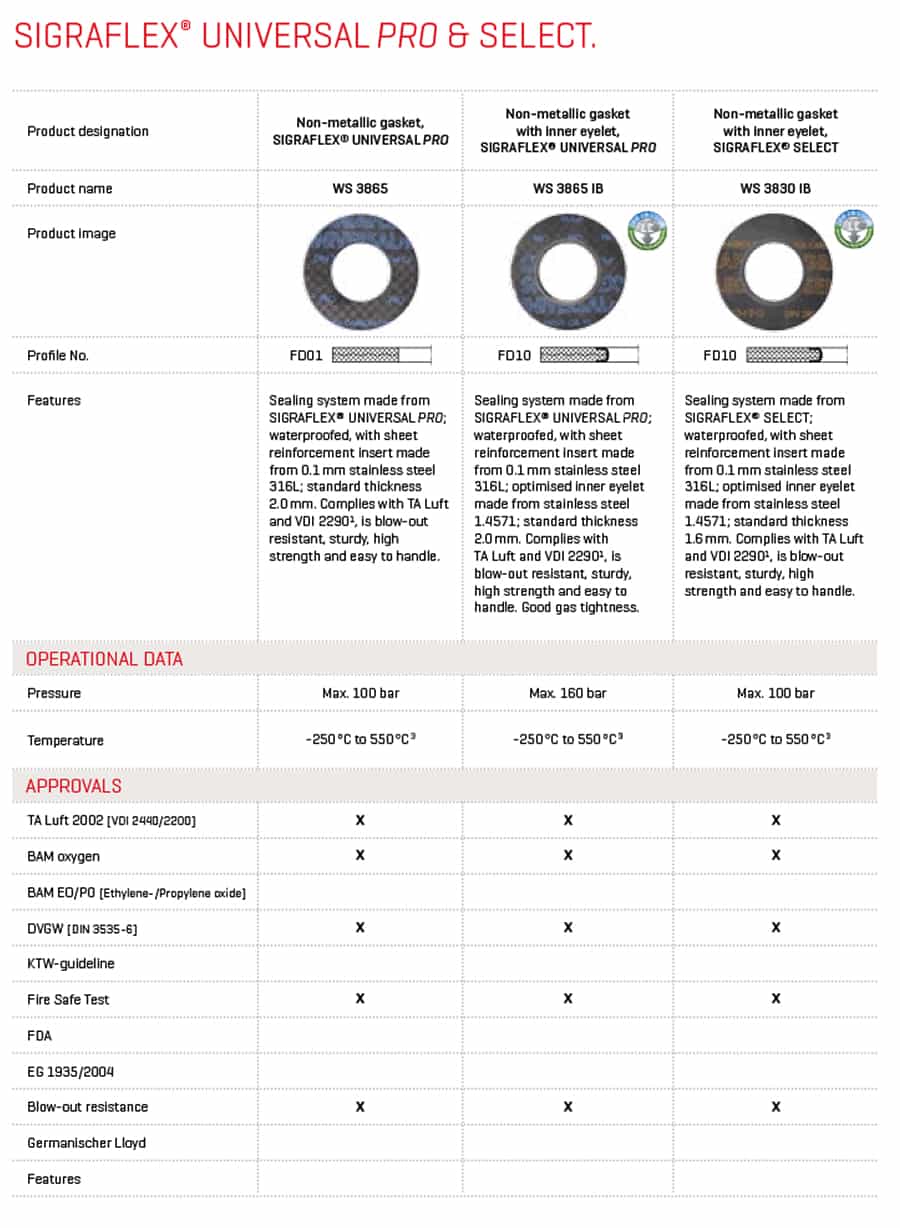

- SIGRAFLEX® UNIVERSAL PRO [WS 3865]

- SIGRAFLEX® SELECT [WS 3830] *

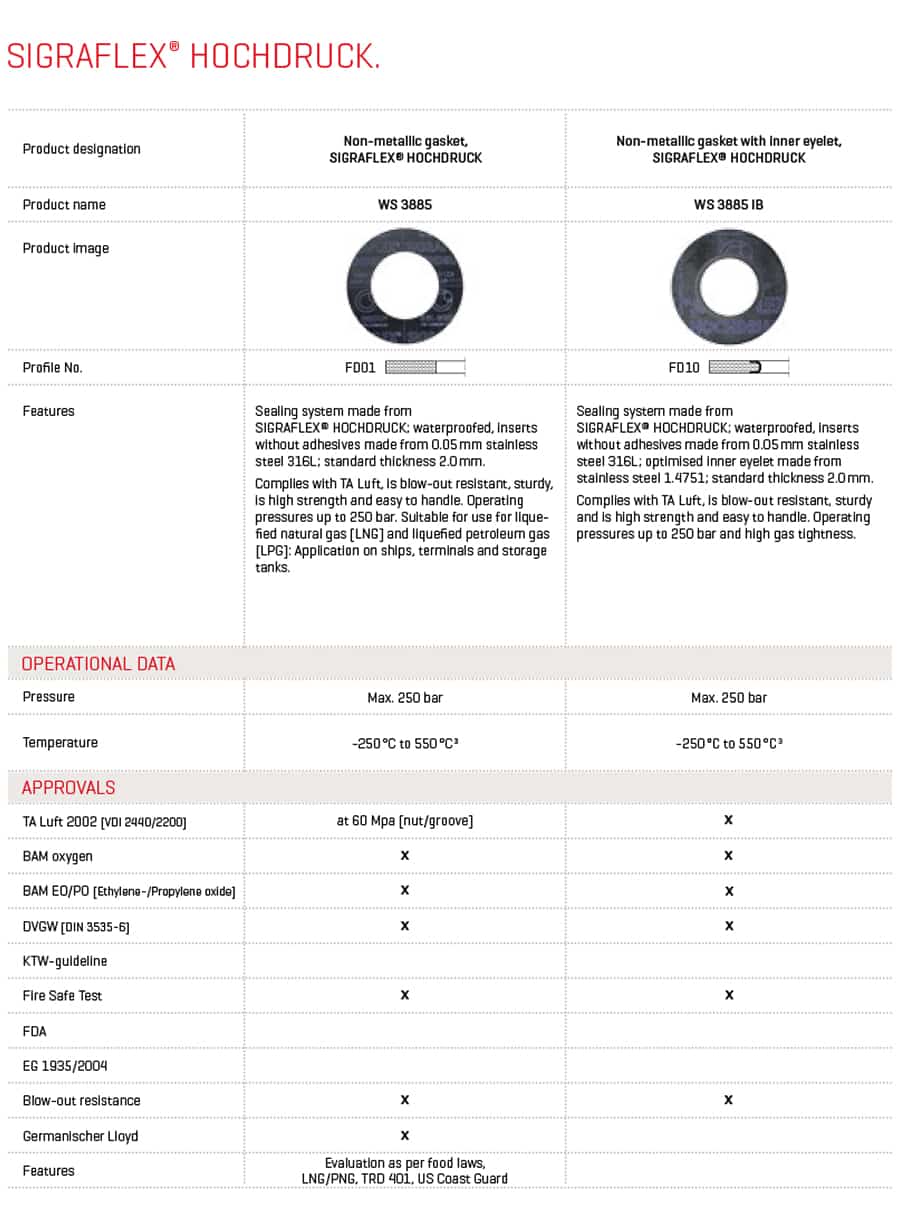

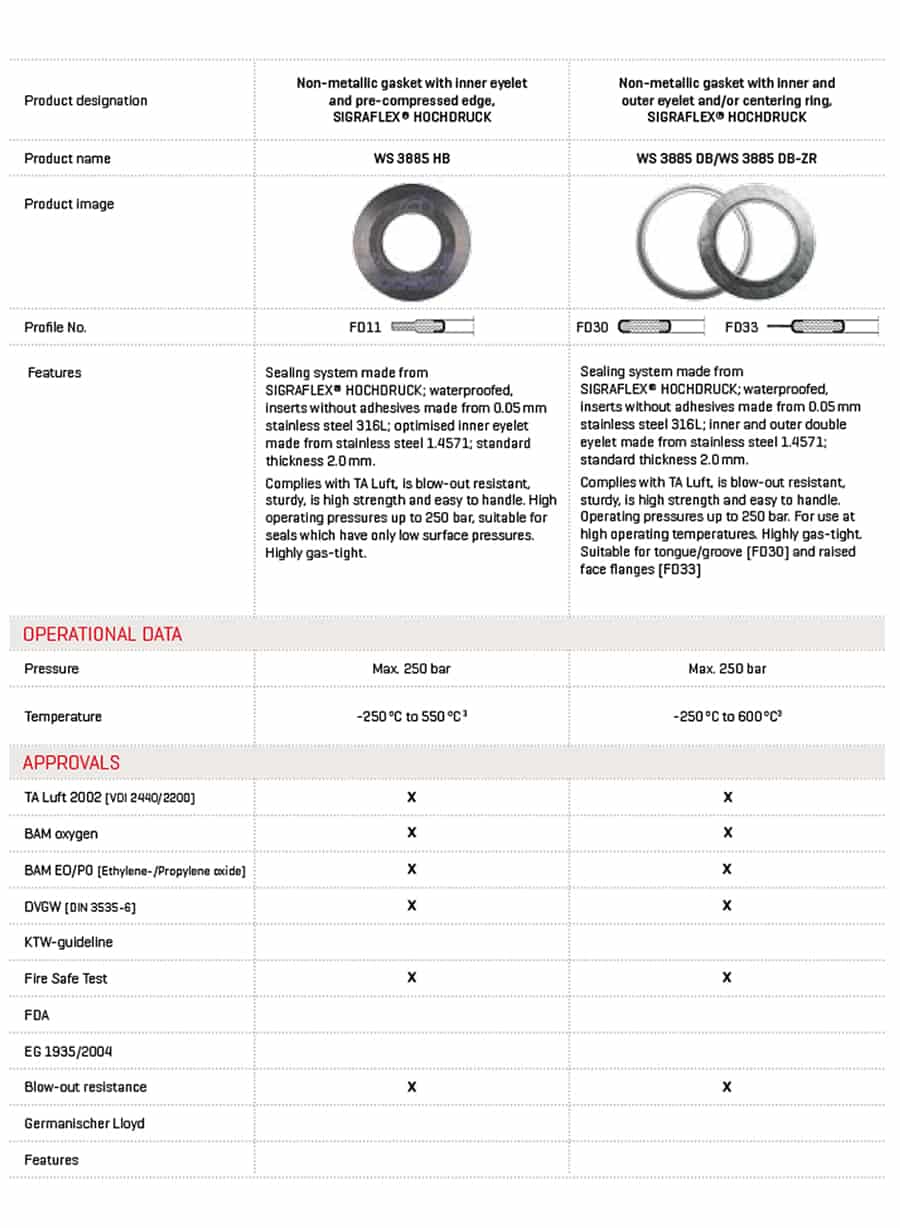

- SIGRAFLEX® HOCHDRUCK [WS 3885]

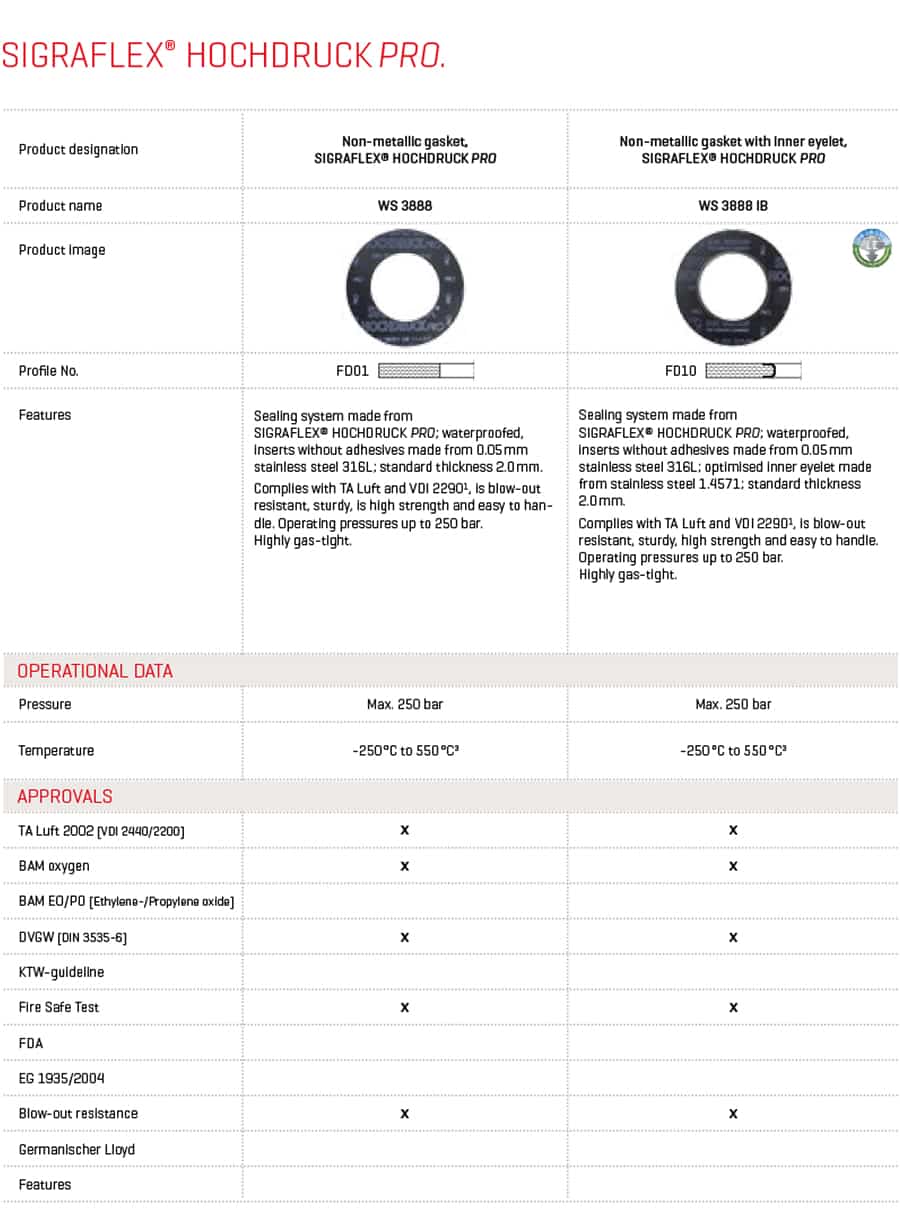

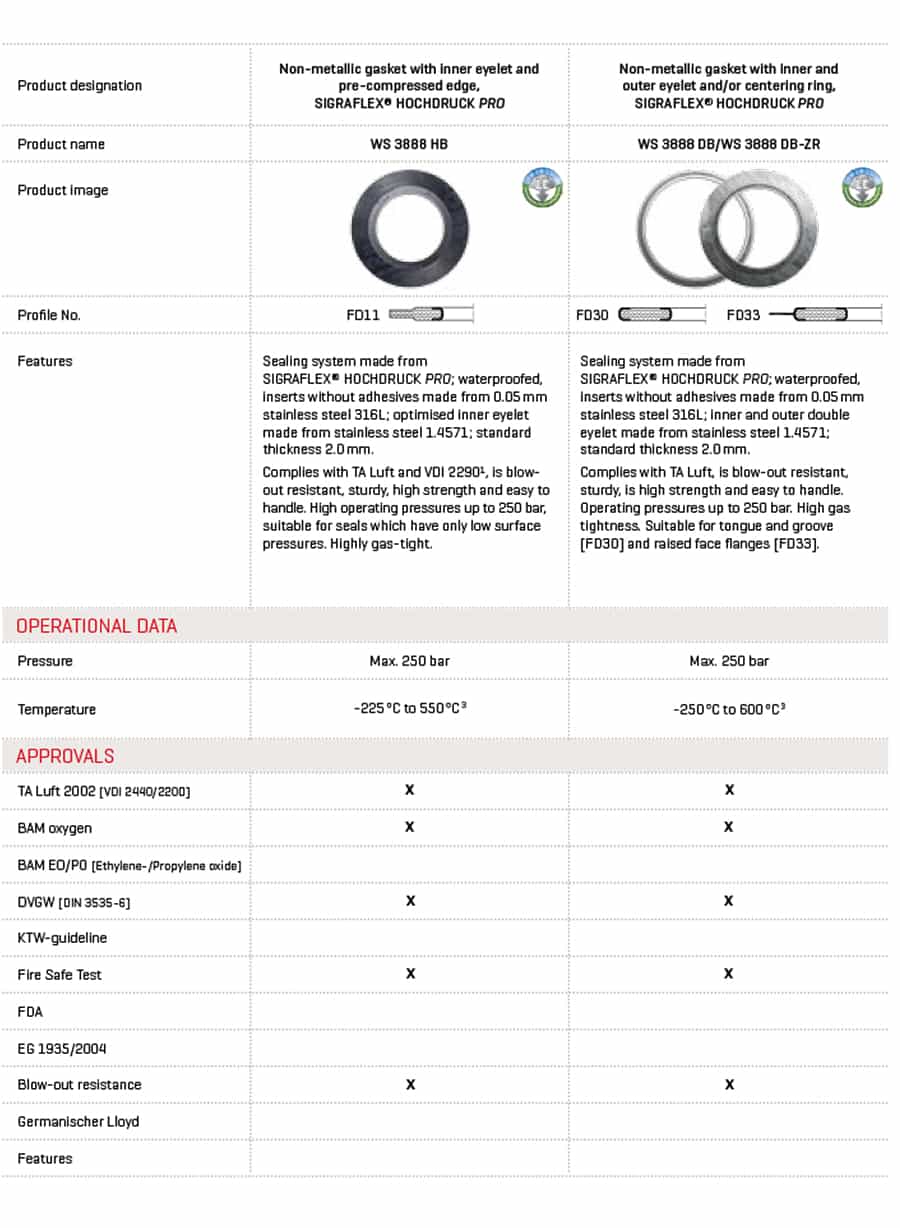

- SIGRAFLEX® HOCHDRUCK PRO [ WS 3888]

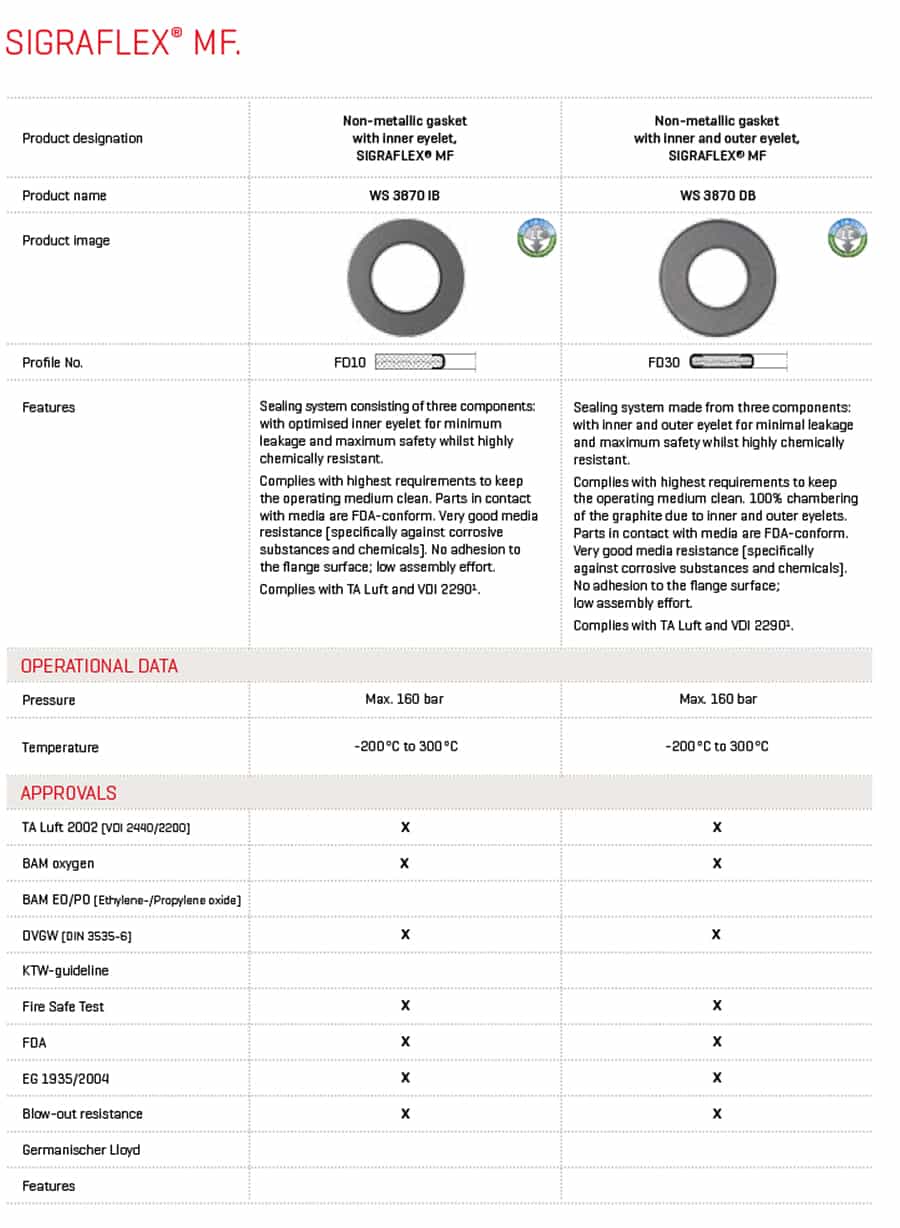

- SIGRAFLEX® MF [WS 3870] *

- SIGRAFLEX® Special type [WS 3875] *

Gaskets made from above mentioned materials are also available with inner eyelets and/or outer eyelets.

[*] Designs are only available with flanges.

Additionally: IDT Profile Overview I FD Series

Additional designs

• Envelope gaskets made from TFMTM with SIGRAFLEX® EMAIL [WS 3825] insert

• Kammprofile serrated/corrugated metal gaskets with graphite layers made from SIGRAFLEX® foils

• Spiral wound gaskets with SIGRAFLEX® graphite filler

Optimised technology clean environment

IDT only processes graphite qualities by SGL Group. SIGRAFLEX® UNIVERSAL and SIGRAFLEX® HOCHDRUCK are among the materials which have been established in the market for years. They are considered state-of-the-art and have proven their value in all industrial applications.

With the commencement of the increased requirements of TA Luft in 2002, it had become necessary to develop new production technologies and product variations to comply with the required emission reductions. The product ranges SIGRAFLEX® PRO, SIGRAFLEX® SELECT and SIGRAFLEX® MF were introduced to meet these requirements and were -mostly with eyelet design – standardised by plant operators.

Based on this environmental and safety relevant background as well as in harmony with applicable environmental protection regulations, various IDT-sealing systems were optimised with regards to their design and production, so that they complied both with the TA Luft requirements as well as the calculatory strength and tightness certificate following DIN EN 1591-1 which has been required since the inception of VDI 2290 in 2012.

The optimised sealing systems are labelled with the IDT envi¬ronmental label for Low Emission [LE]. Subsequent calculations of pipe classes following DIN EN 1591-1 were carried out on the basis of the VCI-guideline for the assembly of flange connec¬tions in process plants and have shown that the leakage rate of 10^-2 mg/[s*m] could be adhered to with all LE versions; in parts even with a bolt quality of 5.6.

In addition to increased leakage requirements and due to higher process temperatures in plants, it also has become necessary to produce the graphite with an increased oxi-dation protection and to equip it with an oxidation inhibitor which is applied directly to the structure of the graphite foil. SIGRAFLEX® APX-foil sets the standard for these applications and has a significantly improved temperature resistance in comparison to standard graphite qualities.