Envelope Gaskets

Envelope Gaskets are widely used in food, pharma, chemical, and petrochemical industries because of their excellent resistance features to ensure operational safety and product purity. Sealmax serves reputed clients in these industries as respected PTFE envelope gasket suppliers as well as gasket manufacturers. The envelope gaskets are available with metallic rings and non-metallic inserts as per the client requirements.

The PTFE envelope gasket from Sealmax, one of the notable PTFE envelope gaskets manufacturers, is produced in accordance with the international safety standards including FDA regulations depending on the desired application. The quality assurance of German engineering can be experienced in the product range offered by Sealmax as well.

Properties

Applications

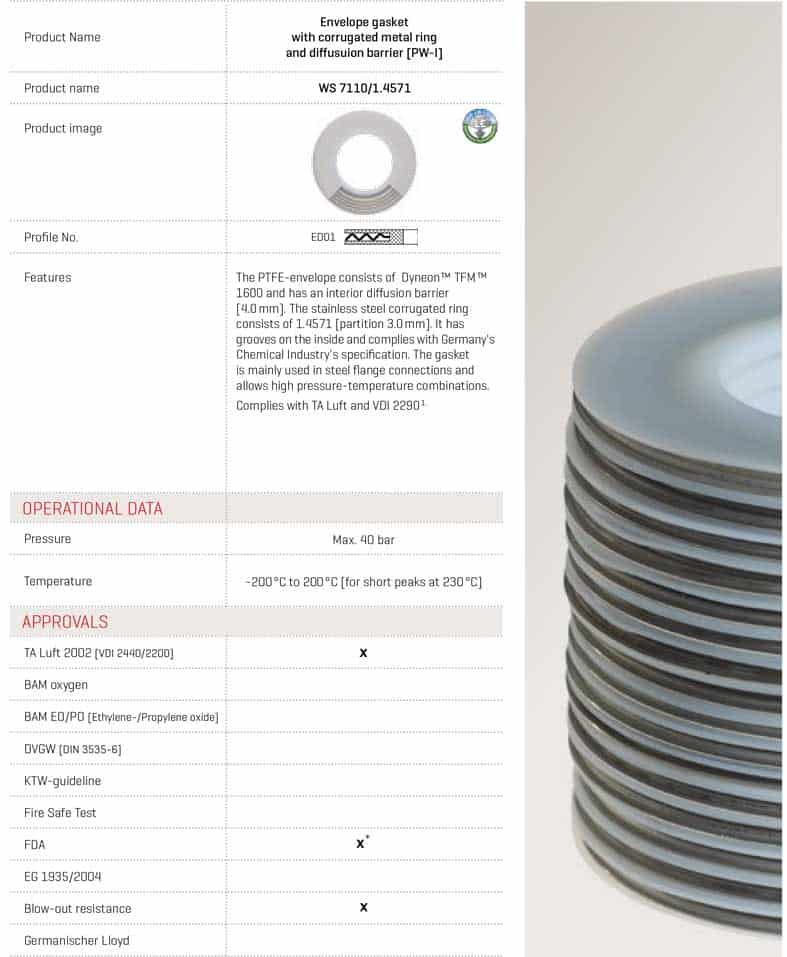

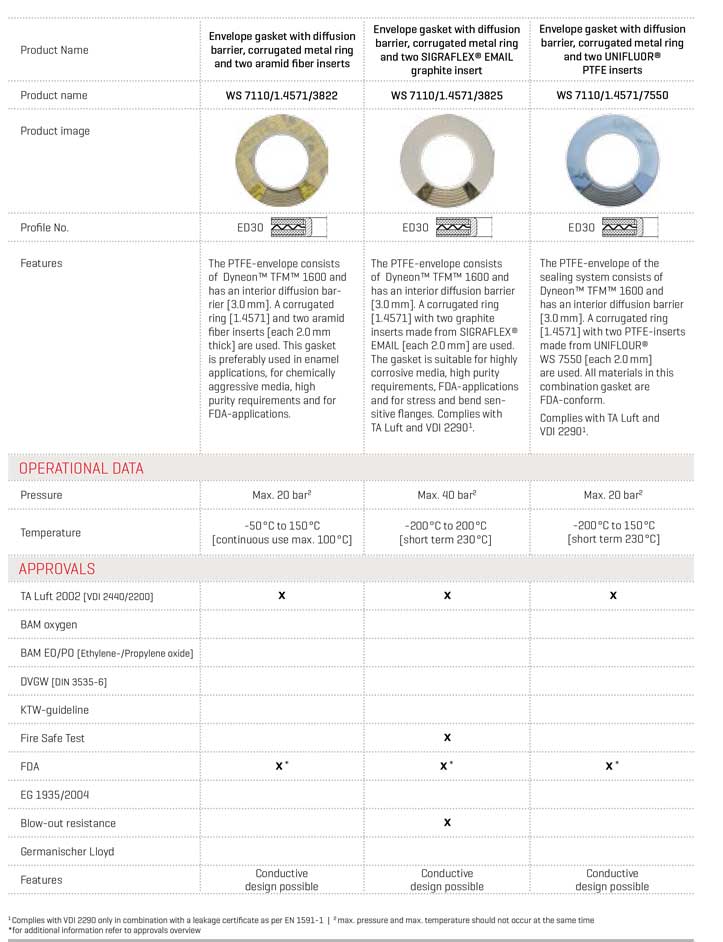

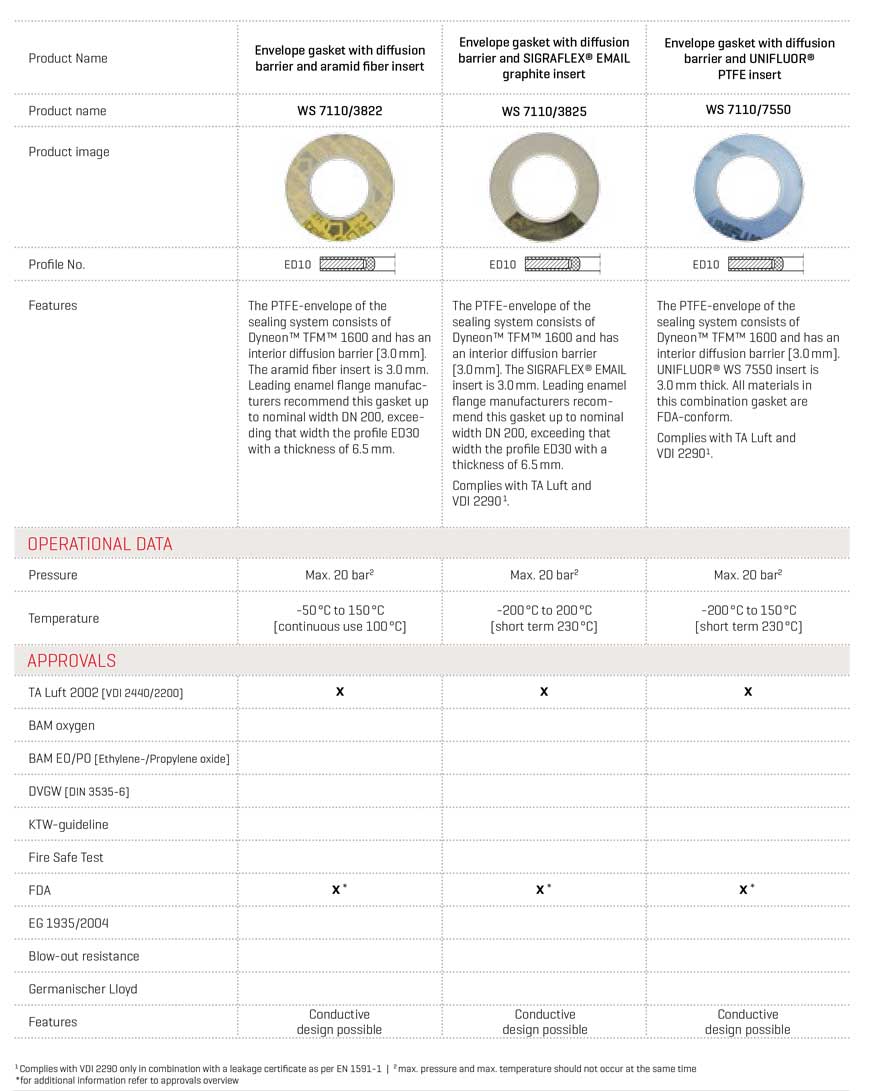

Product Range

Technical delivery conditions for non-metallic inserts as per DIN 28091