TFM™-Elastik gasket.

WS 7110/1.4571 | WS 7110/3822, 3825, 7550 | WS 7110/1.4571/3822, 3825, 7550

Description

The pharmaceutical-chemical industry requires low permeation for sealing applications, high chemical resistance, sturdy mechanical resilience and easier process ability. TFM™, a PTFE of the second generation, has proven itself. The particles melt more easily into a dense, low pore polymer structure due to the more homogeneous crystalline structure; as a result the tightness is significantly improved. High quality 3M™ Dyneon™ TFM™ is used for the envelope gaskets.

PTFE envelope gaskets combine the positive characteristics of TFM™-material with the mechanical behavior of the relevant inserts and have a very high chemical resistance. The positive characteristics are completed with a sturdy diffusion barrier at the inner diameter of the gasket and are optimized across the entire gasket diameter with regards to diffusion. This combination gasket is therefore used for a wide range of applications.

Optimised corrugated ring geometry

The IDT-elastic gasket with metallic corrugated ring insert and diffusion barrier [PW-I] was developed for steel and stainless steel flange connections as well as defined as a standard in the chemical industry. This gasket system can be used at 40 bar and 200 °C simultaneously – which cannot be achieved with classic PTFE gaskets – thanks to the optimised coordination of the mechanical characteristics of the stainless steel corrugated ring with the TFM™-envelope. The corrugated ring insert is also used to increase the bursting and blow-out resistance. The geometric design of the corrugated ring was chosen in such a way that it prevents cutting through the enclosing TFM™-envelope [cross- sectional flat area] and that it has an optimised characteristics profile due to the chosen corrugated partitions of 3.0 mm.

Other TFM™-envelope combinations with inserts have proven themselves in areas which are sensitive to stress, especially for glass lined flange connections. The conditions which are found on the sealing surfaces specifically in enamel applications, such as aggressive media, low surface pressure, sensitive flange surfaces, waviness and warping on the flange sealing surfaces, place high demands on the sealing system.

Non-metallic insert | SIGRAFLEX® EMAIL [WS 3825]

The graphite sheet SIGRAFLEX® EMAIL was developed specifically for use in PTFE-coated non-metallic gaskets, which as a non- metallic insert ensures an ideal interplay of the already outstanding characteristics of the individual components. There is a significant improvement of the sealing technological properties of the PTFE-envelope gaskets thanks to the good recovery property of the graphite, the stainless steel foil insert close to the surface and the combination of the individual layers without adhesives. SIGRAFLEX® EMAIL is a multi-layer sealing sheet made from flexible graphite foil which is reinforced with two 0.05 mm thick stainless foils.

SIGRAFLEX® EMAIL is made in sheet thicknesses of 2.0 mm and 3.0 mm and consists of two 0.5 mm thick outer and one 1.0 mm or 2.0 mm thick inner layers of flexible graphite with the density of 1.1 g/cm³. The compound is made without adhesive using a special process and corresponds therefore to the highest requirements with regards to strength even at high temperatures

TFM™-envelope gasket for food and pharma applications

Quality systems, which regulate the manufacture of medicines and pharmaceutical substances were successfully introduced in the EU. The current good manu facturing practice [GMP] guarantees the safety of pharma ceutical raw materials and products but also applies to cosmetics, food and feed and also includes the relevant quality requirements. IDT has developed an envelope gasket for these applications in consideration of GMP. This sealing system combines the positive characteristics of the TFM™-material as an envelope with those of the non- metallic insert made from the biaxial-oriented UNIFLUOR® [WS 7550]. All materials in this combination gasket are FDA- conform. Possible leaching of filler or colour pigments from the PTFE insert are safely prevented by the TFM™-coating. The sealing system convinces with a high diffusion tightness whilst featuring at the same time an ideal compensation behaviour which is achieved thanks to the low density of the non-metallic insert. The blow-out resistance is increased for designs with additional corrugated ring insert

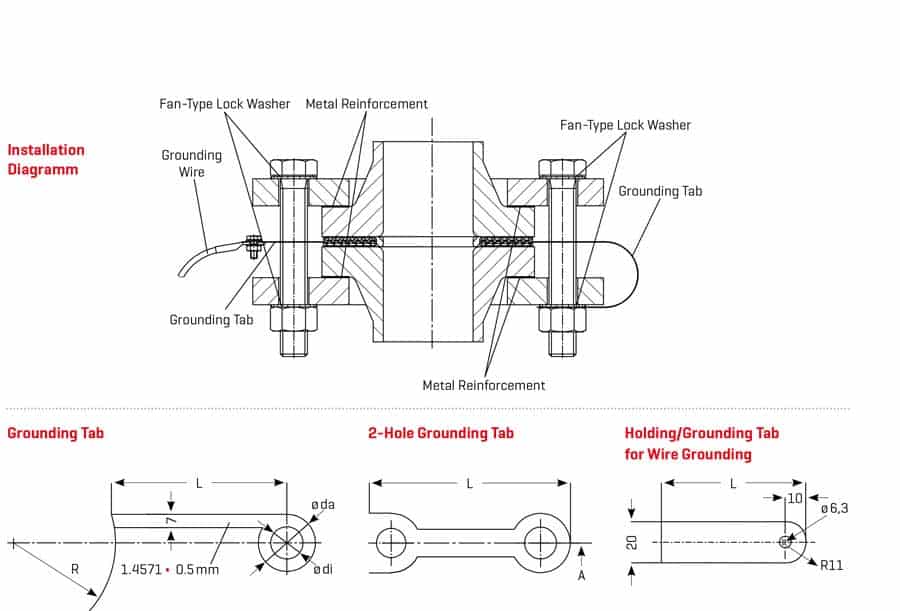

Envelope gaskets for electrostatic discharge

Envelope gaskets can be of a dissipative/conductive design for applications for which a static discharge is necessary and required. For this purpose, it is possible to realize the discharge using an electrically conductive PTFE-envelope made from Dyneon™ TFM™ 6221 WS 7221 and/or using an grounding tab/ grounding wire which is fitted to the outer diameter of the corrugated ring. The discharge of the electrical load is ensured via glass lined pipes, metal reinforcement and fan-type lock washers. The retaining brackets can also be fitted to the corrugated ring as assembly and centering aids.

Grounding and equipotential bonding in pipes with insulating gaskets

The grounding of a plant can be obstructed by insulating components such as gaskets or insulating operating materials like greases. The remaining conductive components have to be connected to each other and grounded when using insulating materials such as spacers made from plastic with high resistance. Alternatively, it is possible to ground every plant part individually. In this environment it is particularly important to consider parts which are not visible from the outside, such as: Ball valves with insulating gaskets or also metal inserts in gaskets.

It depends on the specific conditions if equipotential bonding is necessary for pipelines and gaskets:

Industrial Safety and Health Regulation

The technical regulations on industrial safety and health reflect the regulations on the state of the art, occupational medicine and hygiene and other workplace related findings for the provision and use of equipment and the operation of plants which require monitoring. The Chemistry Committee has created the following professional association regulation “Avoiding Risks of Ignition Resulting from Electrostatic Charges” [BGR 132]. They were adjusted to reflect current law, the developed state of the art and at the same time included in the TRBS 2153 during the development of uniform and coherent rules and procedures. The regulations correspond to the BGI 5127 “Avoiding Risks of Ignition Resulting from Electrostatic Charges” [Information leaflet T 033]. These technical rules apply to the evaluation and avoidance of risks of ignition resulting from electrostatic charges in explosive areas and for the selection and implementation of protective measures to avoid such risks.